Valve Trim Guide – Parts, Materials, API Chart & Selection Criteria

Valve trim refers to the internal components of a valve that directly contact the process fluid and determine how the valve controls flow, pressure, and sealing. Typical trim parts include the disc or plug, seat, stem, bushings, and other wear surfaces. The choice of trim design and material depends on service conditions such as pressure, temperature, corrosion, and erosion. Industry standards, such as the API trim chart, provide common material combinations to simplify specification and ensure consistency across manufacturers.

Table of Contents

1. What is Valve Trim?

Valve trim is the assembly of internal components in a valve that interact with the flowing medium to control and direct fluid movement. These components are designed to withstand specific operating pressures, temperatures, and types of fluid, including corrosive or abrasive media. The trim includes parts such as the disc or plug, seat, stem, and bushings, each with a precise function to maintain flow accuracy, sealing integrity, and operational reliability. Different valve types may require specific trim designs to achieve desired performance characteristics.

Understanding the function and design of valve trim is essential for selecting the right materials and configuration for industrial applications. Proper trim selection helps reduce wear, prevent leakage, and optimize the efficiency of the valve within the system.

2. Primary Functions of Valve Trim

Flow Control: Modulates the rate and direction of fluid movement to maintain stable process conditions and ensure accurate control of the system.

Pressure Regulation: Manages pressure drops across the valve to prevent surges, protect downstream equipment, and maintain system stability.

Sealing Performance: Ensures tight shutoff to minimize leakage, maintain process efficiency, and prevent loss of fluid or pressure.

Noise & Cavitation Reduction: Specialized trims reduce vibration, erosion, and noise in high-velocity or high-pressure applications, protecting both the valve and piping.

Durability: Material selection and design help the valve resist wear, corrosion, and high temperatures, ensuring long-term reliable operation.

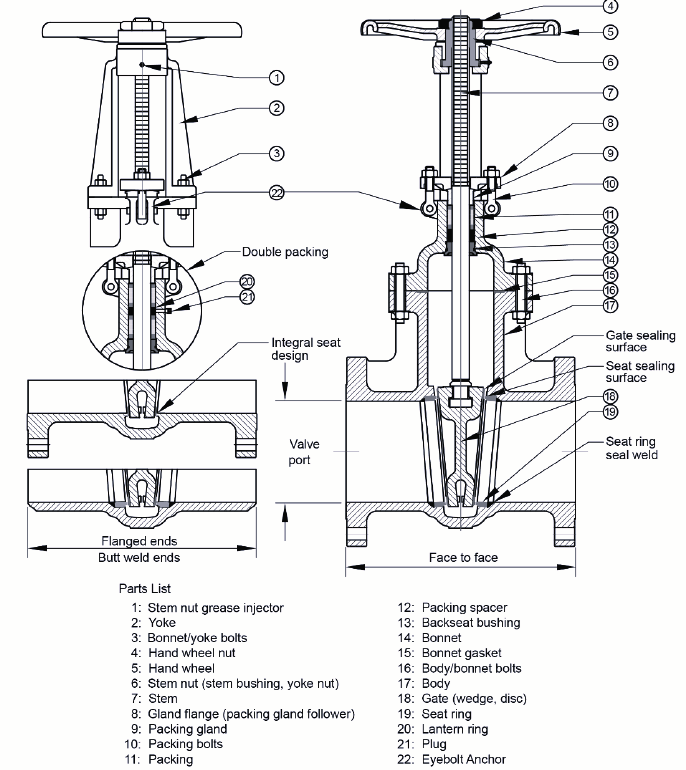

3. Key Components of a Valve Trim

Disc / Plug

The disc or plug is the main throttling element that moves to regulate or stop the flow of fluid. Its shape and surface material determine the flow characteristics, erosion resistance, and durability under varying pressure and temperature conditions.

Seat

The seat forms a seal with the disc or plug to prevent leakage when the valve is closed. It is designed to resist corrosion, erosion, and high temperatures, ensuring reliable shutoff throughout the valve’s service life.

Stem

The stem connects the actuator or handwheel to the disc/plug, transmitting motion to operate the valve. Stems are engineered to handle bending, torsional, and tensile stresses while resisting galling and corrosion.

Bushings

Bushings support and guide the stem, reducing metal-to-metal contact and friction. Materials like PTFE or graphite composites are often used to ensure smooth operation and prevent premature wear, especially in high-cycle or high-pressure valves.

Other Components

Depending on the valve type, additional trim parts may include backseats, sleeves, or cages. These components help improve flow control, minimize wear, and manage pressure drops or turbulence in the valve.

Some components, such as the bonnet interior, gaskets, or packing, may come into contact with the fluid but are not considered part of the wall trim. This is because wall trim specifically refers to the parts that directly modulate flow and form the primary sealing surfaces, while these other parts primarily provide structural support or secondary sealing without controlling the flow path.

4. Valve Trim Materials: How to Choose the Right One

Material Selection: Choosing the right trim material is critical for ensuring durability, corrosion resistance, and reliable performance under the valve’s operating conditions. Trim materials are selected based on the type of fluid, pressure, temperature, and potential for erosion or abrasion.

Common Materials: Stainless steel (304, 316) is widely used for general corrosion resistance. Monel and Inconel alloys are preferred for high-temperature or highly corrosive environments. Tungsten carbide is used in erosive services, while bronze or brass may be applied in low-pressure, non-corrosive systems.

API Trim Numbers: Industry standards, such as API 600 and API 602, assign trim numbers to specific material combinations for disc, seat, and stem. These numbers help engineers standardize material selection and ensure compatibility across different manufacturers.

Hardened Trim: In high-pressure or erosive services, hard-faced materials like Stellite or tungsten carbide overlays are used on seats and discs to extend service life. Solid hard plugs are often applied for smaller valves, while overlays are more practical for larger sizes.

Key Considerations: Selecting trim materials requires evaluating fluid type, temperature, pressure, and required sealing performance. Proper material choice minimizes wear, prevents leakage, and ensures safe operation over time.

5. How to Select the Right Valve Trim: Step-by-Step Approach with Example

Selecting the appropriate valve trim is critical for reliable operation, long service life, and safety. A structured, step-by-step approach helps engineers make informed decisions. The following steps illustrate trim selection for a 5-inch gate valve handling 50% caustic solution inside a process plant, based on API 600 guidelines.

Step 1: Define Process Conditions

Identify the operating pressure, temperature, and fluid characteristics. For our example, the 5-inch gate valve operates at 150 psi, 200°F, handling a highly corrosive 50% caustic solution. These factors determine compatible materials and trims that can withstand chemical attack and erosion.

Step 2: Consult API 600 Trim Numbers

API 600 provides standardized trim numbers specifying combinations of disc, seat, and stem materials. For the given caustic service, API 600 Trim No. 2 is suitable, which uses stainless steel for disc, seat, and stem, providing corrosion resistance and reliable operation in moderate caustic service.

Step 3: Select Seat and Disc Material

The disc and seat are both **stainless steel 316**, which resists caustic corrosion. If erosion or cavitation is a concern, a hard-facing overlay such as **Stellite 6** can be applied to extend service life.

Step 4: Choose the Stem Material

The stem is also **stainless steel 316**, ensuring compatibility with the disc and seat while resisting corrosion and wear. This prevents galvanic corrosion and ensures smooth operation.

Step 5: Verify Bushings and Guides

Select low-friction, corrosion-resistant bushings such as PTFE-lined or graphite composite to reduce stem wear and maintain smooth operation, especially in frequent cycling.

Step 6: Evaluate Sealing Requirements

For tight shutoff in caustic service, a **metal-seat trim** is recommended. Soft seats may degrade rapidly in strong caustic solutions.

Step 7: Confirm Compliance and Service Suitability

Ensure the selected trim combination complies with API 600 Trim No. 2 requirements and the valve’s class rating. Validate all materials against process fluid to minimize risk of corrosion, leakage, or premature failure.

By following these steps, the engineer ensures that the 5-inch gate valve is equipped with API 600 Trim No. 2, featuring stainless steel 316 disc, seat, and stem, optionally hard-faced with Stellite 6 if required, and PTFE/graphite bushings. This configuration balances corrosion resistance, durability, and operational efficiency for 50% caustic service in a process plant.

6. Importance of Correct Valve Trim Selection

Selecting the correct valve trim is critical to ensure safe, efficient, and long-lasting valve operation. The right combination of materials and design minimizes wear, ensures tight shutoff, and maintains consistent flow control under varying operating conditions.

Premature wear and erosion of internal parts: Using unsuitable materials or designs can accelerate erosion of the disc, seat, or stem, especially in high-pressure, high-velocity, or abrasive fluid services. This reduces valve life and increases replacement frequency.

Leakage or failure to achieve desired shutoff: A mismatch between trim material and fluid characteristics can prevent proper sealing, leading to leaks, process inefficiency, or safety hazards. Correct trim ensures tight shutoff and reliable operation.

Excessive noise, vibration, or cavitation: Improperly selected trims may cause turbulent flow, high-pressure drops, or cavitation, resulting in loud operational noise, vibration-induced wear, and potential damage to adjacent piping and equipment.

Reduced operational efficiency and higher maintenance costs: Poor trim selection can create unnecessary pressure losses, limit flow control accuracy, and require frequent maintenance. This increases operational costs and reduces overall process efficiency.

By carefully considering the trim components, material compatibility, and API 600 selection chart, engineers can optimize valve performance, prevent costly downtime, and improve the reliability of the entire piping system. Proper trim selection ensures safety, longevity, and consistent process control in demanding industrial applications.

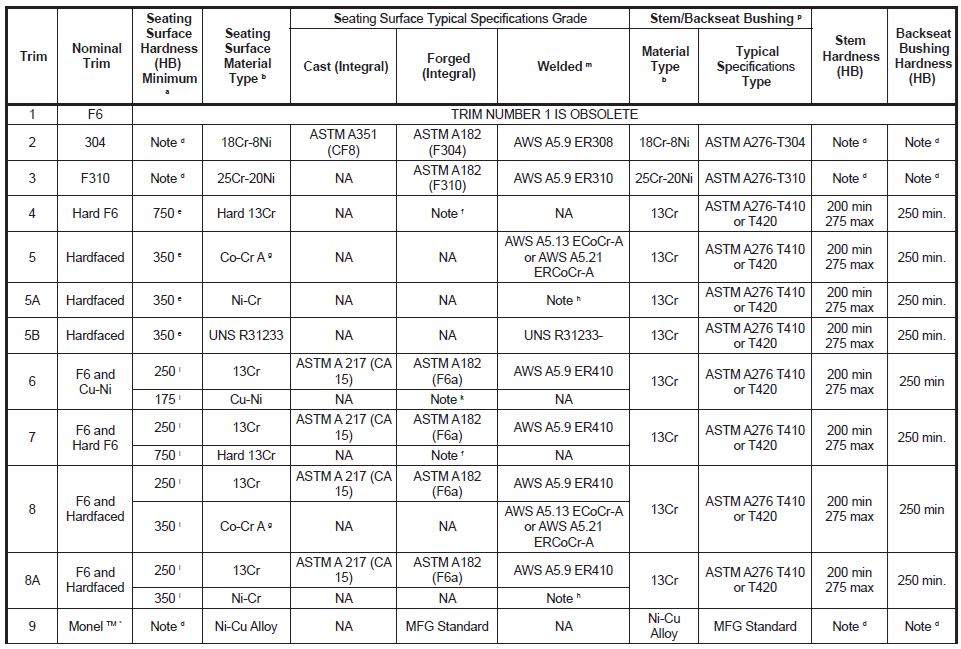

7. API Valves Trim Table (Trim Chart)

The API 600 Trim Table standardizes material combinations for valve internals such as the disc, seat, and stem. Each trim number represents a specific set of materials and surface treatments, ensuring consistent performance and compatibility across manufacturers and applications.

The following table summarizes the first nine (9) trim combinations defined in API Standard 600 – Table 8. The full standard includes additional trims up to Trim 20. For complete information and the latest revisions, users should always consult the official API publication.

API Standard 600 – Trim Chart (Partial)

Note: Only the first ten trim numbers are listed above to illustrate the format and material types. API Standard 600 defines additional trims up to Trim 20 and beyond.

For complete and up-to-date information, always refer to the latest API 600 publication.

Official reference: https://www.api.org

8.Frequently Asked Questions

A valve trim refers to the internal components of a valve that control flow, such as the plug, seat, stem, disc, and cage. The trim determines the valve's flow characteristics, pressure drop, noise, and resistance to erosion or corrosion, and is critical in selecting a valve for specific applications.

Different materials are chosen to withstand specific operating conditions like temperature, pressure, and corrosiveness of the fluid. Common trim materials include stainless steel, hardened alloys, and special coatings to enhance durability, reduce wear, and maintain a tight seal over time.

Trim design, such as globe, cage, or characterized trims, defines the flow path and the valve’s inherent flow coefficient. It influences the precision of control, throttling behavior, and stability under high-velocity conditions. Proper trim selection ensures smooth operation and avoids cavitation or vibration.

Standard trims are suitable for normal pressure drops, while anti-cavitation trims are specially designed to reduce the formation of vapor bubbles in high-pressure drop applications. They protect the valve and piping from erosion, vibration, and noise caused by collapsing cavitation bubbles.

Some valves allow for trim replacement in-line, meaning the internal components can be serviced without removing the entire valve body. However, larger valves or certain designs may require full disassembly. In-line replacement reduces downtime and maintenance costs when properly designed.

The trim design and material significantly influence noise generation by controlling fluid velocity, pressure drop, and turbulence. Multi-stage or cage-type trims can reduce noise in high-pressure applications by gradually dissipating energy, ensuring safe and comfortable operation in sensitive environments.

No, trims are specifically designed for particular valve models and applications. Using the wrong trim can lead to poor flow control, leakage, or damage. Always refer to the valve manufacturer’s guidelines to ensure compatibility and optimal performance.

API standards like API 600 or API 602 define trim classifications, materials, and performance criteria for valves. Referring to these standards ensures the selected trim meets safety, pressure, and flow requirements. Many manufacturers provide trim charts referencing API trim numbers for quick selection.