Classification of Pumps: Types, Working Principles, and Applications

⏱️ Estimated Reading Time: 10 min

🗓️ Last Updated: 29 August 2025

Pumps are essential machines used to move fluids efficiently across industries. This page explores different types of pumps, their operating principles, and industrial applications.

1. Introduction

This article provides a comprehensive overview of the classification of pumps, including the types of pumps, their working principles, and their industrial applications. A pump is a mechanical device designed to move fluids from one place to another by creating pressure or suction. It converts mechanical energy, typically from an electric motor or engine, into hydraulic energy, forcing the fluid through a piping system efficiently.

Different pumps operate using different mechanisms. For example, centrifugal pumps use a rotating impeller to create flow, while positive displacement pumps trap fluid in a chamber and force it out using pistons, gears, or diaphragms. Pumps are essential in numerous applications such as water supply, chemical processing, and industrial fluid handling, ensuring reliable transfer and pressure control.

Pumps are optimized for incompressible fluids (liquids), whereas compressors and fans are used for gases, since gases behave differently under pressure. Understanding the classification and operation of pumps helps engineers and technicians select the right pump for specific applications.

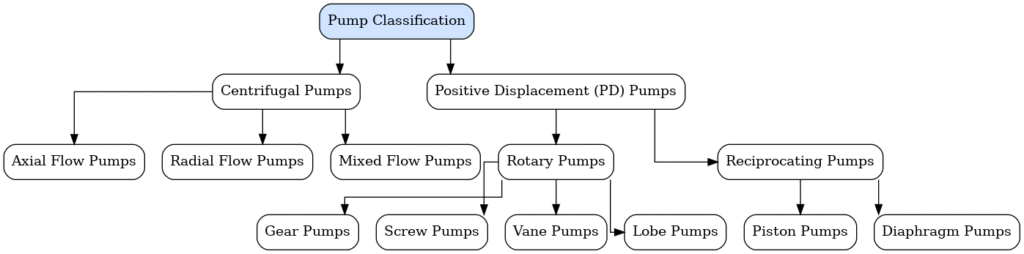

2. Classification of Pumps

Pumps can be broadly classified into two main categories based on how they move fluids: centrifugal pumps and positive displacement pumps. Each category operates on distinct principles, making them suitable for specific applications. Understanding these classifications helps engineers select the most efficient pump for a given task, considering factors such as flow rate, pressure, fluid type, and system requirements.

Centrifugal Pumps

Centrifugal pumps are the most widely used type of pump in industries. They operate by converting rotational kinetic energy from an impeller into hydrodynamic energy, moving fluid outward through centrifugal force. These pumps are ideal for handling large volumes of liquids at relatively low pressures and are commonly used in water supply, HVAC systems, and chemical processing.

Radial Flow Pumps

Radial flow pumps move fluid perpendicular to the pump shaft. The fluid enters the impeller axially and exits radially, creating high pressure and moderate flow rates. They are particularly suitable for applications requiring high head, such as boiler feedwater systems and water distribution networks.

Axial Flow Pumps

Axial flow pumps propel fluid parallel to the pump shaft using a propeller-like impeller. They provide high flow rates at low pressures, making them suitable for applications such as flood control, circulation of cooling water, and irrigation systems. These pumps are less efficient at generating high head compared to radial flow pumps.

Mixed Flow Pumps

Mixed flow pumps combine features of radial and axial flow designs. Fluid exits the impeller at an angle between radial and axial directions, offering a balance of high flow rate and moderate pressure. They are often used in applications such as municipal water supply, flood control, and large-scale irrigation.

Positive Displacement Pumps

Positive displacement pumps move a fixed amount of fluid with each cycle, trapping it in a chamber and forcing it out using pistons, gears, or diaphragms. They are ideal for applications requiring precise flow control or high pressure, such as chemical dosing, oil transfer, and hydraulic systems. These pumps are less sensitive to changes in system pressure compared to centrifugal pumps, making them suitable for viscous or shear-sensitive fluids.

Rotary Pumps

Rotary pumps move fluid by trapping it in cavities between rotating components and the pump casing. Common types include gear pumps, lobe pumps, and vane pumps. They are ideal for handling viscous liquids, lubricants, and chemical solutions, providing steady flow at moderate pressures with minimal pulsation.

Reciprocating Pumps

Reciprocating pumps use pistons or plungers that move back and forth to draw in and discharge fluid. They are capable of generating very high pressures and are suitable for applications requiring precise metering, such as boiler feedwater, hydraulic systems, and chemical injection. Flow from these pumps is pulsating, which may require dampening in certain systems.

3. Comparison of Centrifugal and Positive Displacement Pumps

The following table provides a detailed comparison between centrifugal pumps and positive displacement pumps based on key operational, design, and application factors:

| Feature | Centrifugal Pumps | Positive Displacement Pumps |

|---|---|---|

| Operating Principle | Converts rotational kinetic energy of an impeller into fluid velocity and pressure. | Traps a fixed volume of fluid and displaces it mechanically through a chamber. |

| Flow Type | Continuous, smooth flow; varies with system pressure. | Fixed volume per cycle; provides consistent flow regardless of pressure. |

| Pressure Capability | Best for low to moderate pressure applications. | Capable of generating very high pressures. |

| Flow Rate | High flow rates possible; less effective for low-volume precision applications. | Limited flow per cycle; ideal for precise metering or low-flow applications. |

| Efficiency | High efficiency near best efficiency point (BEP); drops significantly off BEP. | Consistent efficiency over wide range of pressures; less sensitive to system conditions. |

| Fluid Viscosity | Handles low-viscosity fluids well; efficiency decreases with high viscosity. | Handles high-viscosity and shear-sensitive fluids effectively. |

| Pulsation | Flow is smooth; minimal pulsation. | Flow is pulsating; may require dampeners for smooth delivery. |

| Maintenance | Generally low maintenance; simpler design. | More complex; requires frequent maintenance due to moving parts. |

| Typical Applications | Water supply, HVAC, chemical transfer, cooling systems. | Chemical dosing, oil transfer, high-pressure injection, hydraulic systems. |

| Cost | Generally lower initial cost for same capacity. | Higher cost due to complex construction and precision components. |

4. Applications of Different Pump Types in Industry

Pumps play a critical role in a wide range of industrial applications, with the selection of pump type directly influencing operational efficiency, reliability, and maintenance requirements.

Centrifugal Pumps: These pumps are widely used for high-flow, low to moderate pressure applications. They are ideal for water supply networks, HVAC systems, irrigation, and cooling water circulation in power plants. In the chemical and process industries, centrifugal pumps handle large volumes of low-viscosity fluids, such as acids, bases, and solvents, providing smooth and continuous flow.

Positive Displacement Pumps: Rotary and reciprocating pumps are preferred where precise flow control, high pressure, or handling of viscous fluids is required. They are extensively used for chemical dosing, lubrication systems, oil transfer, food processing, and hydraulic circuits. In industries such as petrochemicals, pharmaceuticals, and heavy machinery, positive displacement pumps ensure accurate and consistent delivery even under varying system pressures.

Specialized Applications: Some pump types are designed for niche purposes. Gear pumps are used in fuel transfer and lubrication systems, diaphragm pumps handle corrosive or abrasive chemicals, and peristaltic pumps are suitable for sterile or shear-sensitive fluids. Selecting the right pump type based on fluid properties, pressure requirements, and flow rates ensures optimal performance, reduced wear, and lower operational costs across industrial operations.

5. Selection Criteria for Pumps

Selecting the appropriate pump is crucial for ensuring optimal performance, energy efficiency, and long-term reliability in industrial and commercial applications. The following factors should be meticulously evaluated during the pump selection process:

1. Flow Rate and Pressure Requirements

- Flow Rate: Determine the required flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM). This is essential for sizing the pump to meet system demands.

- Pressure (Head): Assess the total dynamic head (TDH), which includes the vertical lift, friction losses, and any additional system resistances. This ensures the pump can overcome system pressure requirements effectively.

2. Fluid Characteristics

- Viscosity: High-viscosity fluids may require positive displacement pumps, while low-viscosity fluids are suitable for centrifugal pumps.

- Density and Specific Gravity: These properties affect the power required to move the fluid.

- Temperature: Ensure the pump materials can withstand the operating temperature of the fluid.

- Chemical Compatibility: Select materials that are resistant to corrosion or degradation by the fluid.

- Solids Content: If the fluid contains solids, choose a pump designed to handle abrasive or particulate-laden fluids.

3. Net Positive Suction Head (NPSH)

- NPSH Required (NPSHr): Minimum pressure required at the suction port of the pump to prevent cavitation.

- NPSH Available (NPSHa): Actual pressure available at the pump's suction. NPSHa must exceed NPSHr by a safety margin to avoid cavitation.

4. Pump Efficiency and Energy Consumption

- Best Efficiency Point (BEP): Choose a pump that operates near its BEP to minimize energy consumption and reduce wear.

- Variable Frequency Drives (VFDs): Consider using VFDs to adjust pump speed according to demand, enhancing efficiency and reducing energy costs.

5. Maintenance and Reliability

- Maintenance Requirements: Evaluate the ease of maintenance and availability of spare parts.

- Reliability: Consider the pump's expected lifespan and the manufacturer's reputation for reliability.

- Critical Applications: For critical processes, select pumps with redundant features or backup systems to ensure continuous operation.

6. Environmental and Operational Conditions

- Ambient Conditions: Assess factors like ambient temperature, humidity, and exposure to corrosive environments.

- Space Constraints: E

6. Advantages and Limitations of Different Pumps

Understanding the strengths and weaknesses of each pump type is essential for selecting the most suitable pump for industrial and commercial applications. Each pump offers unique operational benefits and limitations depending on its design, the fluid being handled, and process requirements.

Centrifugal Pumps

- Advantages: Simple design, cost-effective, easy to install and maintain. Excellent for handling high flow rates of low to medium viscosity fluids. Can operate continuously with minimal operator intervention.

- Limitations: Less suitable for high-viscosity or shear-sensitive fluids. Performance drops significantly at low flow rates or under high system pressure. Cannot provide precise flow control without additional devices.

- Applications: Water supply systems, HVAC circulation, chemical processing, irrigation, and wastewater management.

Positive Displacement Pumps

- Advantages: Provides accurate and consistent flow regardless of system pressure. Ideal for high-viscosity or shear-sensitive fluids. Capable of generating high pressures. Suitable for precise dosing and metering applications.

- Limitations: Generally more complex and expensive than centrifugal pumps. Requires more frequent maintenance due to moving parts. Limited to lower flow rates compared to centrifugal pumps. May be sensitive to dry running and cavitation.

- Applications: Chemical dosing, oil and fuel transfer, hydraulic systems, food and beverage processing, and pharmaceutical manufacturing.

Key Takeaways

- Selection must balance flow requirements, fluid properties, system pressure, and operational efficiency.

- Centrifugal pumps are ideal for high-volume, low-viscosity applications, while positive displacement pumps excel in precise, high-pressure, or viscous fluid scenarios.

- Understanding these trade-offs ensures reliability, energy efficiency, and long-term performance in industrial processes.

7. Conclusion

Understanding the classification, types, working principles, and applications of pumps is essential for selecting the right equipment for any fluid-handling system. Centrifugal pumps are ideal for high-flow, low-pressure applications, while positive displacement pumps provide precise flow and high-pressure capabilities. Proper pump selection, considering system requirements and fluid properties, ensures efficiency, reliability, and longevity in industrial and commercial processes.

Related Content

Fans and Blowers

Explore page about Fans & Blowers, Types, Selction Criteria and Applications