Pressure Vessels: Design, Materials, Standards, and Safety Overview

Pressure vessels are essential equipment in oil & gas, chemical, power, and process industries. They are designed to safely store or process fluids under high pressure, following strict engineering standards such as ASME Section VIII. From material selection to inspection and testing, understanding pressure vessels ensures safety, efficiency, and regulatory compliance across industrial applications.

What Exactly Are Pressure Vessels?

Pressure vessels are specialized containers designed to store fluids or gases under high pressure. They range in size from small scuba tanks to massive industrial structures and serve a variety of purposes across industries.

The design of pressure vessels is critical because they must withstand extreme internal forces. Most vessels are cylindrical or spherical and are made from robust materials such as steel, aluminum, or composites.

The choice of material and shape depends on:

- The type of substance they will contain.

- The environmental stresses they must endure.

Before being put into service, every pressure vessel undergoes rigorous testing and certification to ensure compliance with strict safety standards. This process typically evaluates:

- Structural integrity (can it safely handle the design pressure?).

- Operational limits (how it performs under specific temperatures and pressures).

Common types of pressure vessel equipment used in industry include:

- Separators – Equipment that separates oil, gas, and water from production streams. Two-phase separators handle gas-liquid separation, while three-phase separators can also separate water, ensuring the downstream processes receive clean and usable products. They are commonly used in upstream oil & gas facilities and operate under pressures ranging from a few psi to several hundred psi depending on the field conditions.

- Reactors – Vessels designed to facilitate chemical reactions under controlled temperature and pressure. Examples include hydrocrackers and catalytic reformers, which are critical in refining and petrochemical industries for converting raw feedstocks into valuable products. These reactors often operate at high temperatures (up to 450°C) and pressures (hundreds of psi), requiring precise design and robust materials to ensure safe and efficient reactions.

- Heat Exchangers – Devices that transfer heat efficiently between two or more fluids. Common types include shell & tube and plate heat exchangers, widely used for heating, cooling, or condensing fluids in chemical, power, and process industries. They typically operate under moderate to high pressures and temperatures, and their design must account for thermal expansion, corrosion, and fouling.

- Scrubbers – Systems used to remove impurities, particulates, or harmful gases from industrial gas streams. They help meet environmental regulations and protect equipment by cleaning exhaust gases before release or further processing. Scrubbers are extensively used in petrochemical plants, refineries, and power stations, often operating at low to moderate pressures and handling corrosive or particulate-laden gas streams.

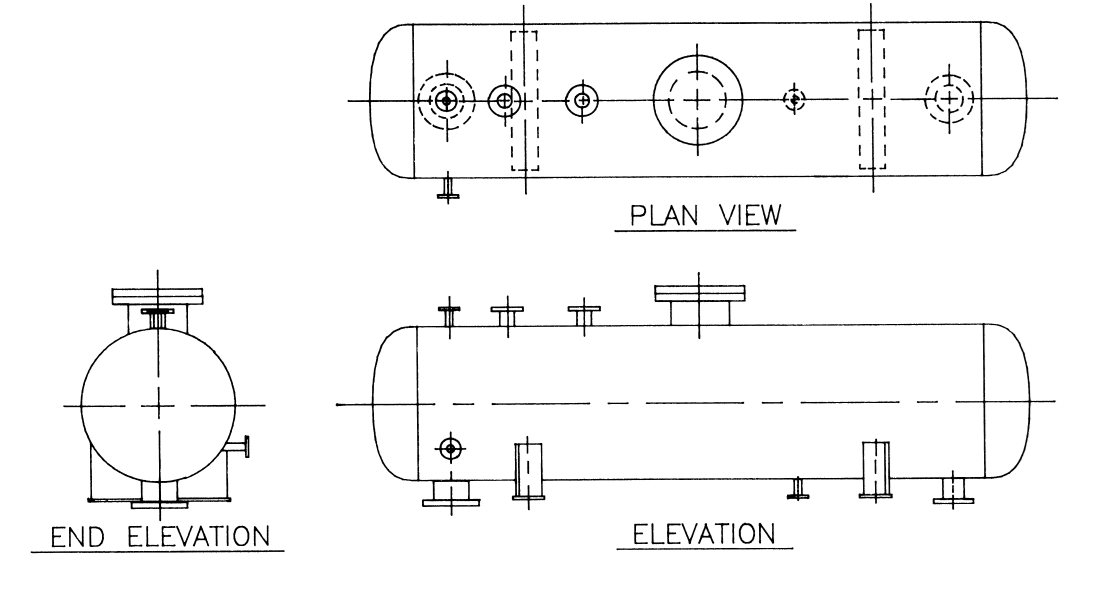

Figure: Plan and Elevation views of horizontal Pressure Vessel

Pressure Vessels vs. Storage Tanks: Key Differences

Pressure vessels and storage tanks are often confused, but they serve distinct purposes and operate under very different conditions. Pressure vessels are designed to safely contain fluids or gases at pressures significantly above atmospheric levels, requiring robust materials, strict engineering standards, and thorough testing. Storage tanks typically store liquids at or near atmospheric pressure and are simpler in design and construction.

The table below highlights the main differences between these two types of industrial containers:

| Feature | Pressure Vessels | Storage Tanks |

|---|---|---|

| Pressure Range | Operate above atmospheric pressure, typically from a few psi up to 10,000–15,000 psi in industrial applications | Typically hold contents at near-atmospheric pressure (MAOP ≤ 15 psi) |

| Example | Industrial boilers, compressed gas cylinders | Fuel storage tanks, water reservoirs |

Understanding these differences is important because pressure vessels experience much higher stresses, requiring careful design, high-quality materials, precise fabrication, and rigorous inspection. Storage tanks, in contrast, are easier to construct and maintain, as they operate at low pressures and are generally less complex in terms of engineering requirements.

Design Considerations

Pressure vessels operate under extreme conditions, including high pressures, elevated temperatures, and corrosive environments. To prevent failures, leaks, or catastrophic accidents, they must adhere to strict engineering standards and precise design practices.

Key factors in designing a safe and efficient pressure vessel include:

- Design Pressure – Determines the maximum internal stress the vessel can safely withstand. Accurate calculation is essential for structural integrity and safety compliance.

- Material Selection – Materials must balance strength, corrosion resistance, and cost. Carbon steel (e.g., SA-516 Gr. 70) is common, while stainless steel or nickel alloys are used for highly corrosive services.

- Structural Integrity – Precision welding and reinforcement of joints, nozzles, and connections are critical to prevent failure under pressure.

- Temperature Effects – High or low operating temperatures affect wall thickness, material choice, and reinforcement needs.

- Shape & Orientation – Cylindrical or spherical vessels distribute stress differently; vertical or horizontal orientation affects integration, stability, and maintenance.

- Head Design – Common options include:

- Hemispherical – best for high-pressure applications.

- Elliptical – balanced strength and cost.

- Flanged & Dished – widely used in industry.

- Openings & Connections – Nozzles, manholes, and instrument ports must be carefully positioned to avoid weak points and facilitate inspection and maintenance.

By carefully addressing these design considerations, engineers ensure that pressure vessels perform safely and reliably throughout their service life while complying with regulatory standards.

Materials Used in Pressure Vessels

Selecting the right material is critical to ensure durability, safety, and performance of pressure vessels. The choice depends on the type of fluid, operating pressure, temperature, and the potential for corrosion.

- Steel (Most Common Choice)

- Carbon Steel – Affordable, strong, and capable of handling high pressures in most industrial applications.

- Stainless Steel – Offers excellent corrosion resistance, ideal for harsh or corrosive environments.

- Nickel Alloys (For Extreme Conditions)

- Resistant to heat, corrosion, and aggressive chemicals.

- Example: Hastelloy, widely used in chemical and petrochemical industries for demanding applications.

- Aluminum & Titanium (Specialized Uses)

- Aluminum – Lightweight and corrosion-resistant but has lower pressure tolerance, used where weight savings are critical.

- Titanium – Expensive but provides exceptional strength and corrosion resistance, often used in aerospace and chemical plants.

Proper material selection ensures the pressure vessel can safely operate under its design conditions while maximizing longevity and minimizing maintenance.

Pressure Vessel Standards (ASME BPVC Section VIII)

The safety and reliability of pressure vessels are ensured through compliance with the ASME Boiler and Pressure Vessel Code (BPVC), Section VIII. This standard provides engineering rules, material requirements, and testing guidelines for pressure vessels operating at various pressures.

| Division | Key Features |

|---|---|

| Division 1 | Basic rules for vessels with MAOP > 15 psi. Covers U, UV, and UM certification marks. |

| Division 2 | Stricter rules for high-pressure vessels (up to 15,000 psi). Requires advanced materials and thorough testing. |

| Division 3 | For ultra-high-pressure applications, such as in oil & gas or nuclear reactors. |

Following ASME standards helps ensure safety, regulatory compliance, reduced accident risks, longer vessel lifespan, and smoother approvals without costly redesigns.

Inspection and Testing of Pressure Vessels

To ensure the structural integrity and safe operation of pressure vessels, multiple inspection and testing techniques are employed. These methods detect defects, confirm material quality, and verify that the vessel meets design specifications.

- Visual Testing (VT)

Purpose: Identifies surface defects before commissioning and during routine maintenance.

- Frequency: Mandatory every five years, and after installation or repairs.

- Process: A certified inspector examines internal and external surfaces for cracks, dents, deformations, corrosion, blistering, fluid leakage, and weld defects.

- Ultrasonic Testing (UT)

Principle: Uses high-frequency sound waves to detect hidden flaws and measure wall thickness.

- Process: A transducer sends ultrasonic waves into the material; disruptions in reflections indicate defects.

- Advantage: Effective for subsurface cracks and erosion assessment.

- Radiographic Testing (RT)

Method: Uses X-rays or gamma rays to create images of internal structures.

- Detection: Voids, inclusions, density variations, and weld defects (porosity, lack of fusion).

- Pros: Highly repeatable with minimal surface preparation.

- Cons: Expensive and requires radiation safety protocols.

- Magnetic Particle Testing (MT)

Applicability: Only for ferromagnetic materials such as carbon steel.

- Process: A magnetic field is induced in the vessel; iron particles highlight surface-breaking defects in welds or stress points.

- Liquid Penetrant Testing (PT)

- Steps: Apply penetrant dye, allow dwell time, remove excess, and apply developer to reveal flaws.

- Best for: Non-porous materials like stainless steel.

- Pressure Testing (ASME Code Requirement)

- Hydrostatic Test: Uses water at 1.5× design pressure.

- Pneumatic Test: Uses air or nitrogen at 1.2–1.5× design pressure (safer due to lower stored energy).

- Process: Pressurize and hold for ≥10 minutes, inspect for leaks using fluorescent tracers.

- Timing: Conducted post-installation, post-repair, or during shutdowns.

By following these inspection and testing procedures, engineers can maintain vessel safety, extend service life, and comply with regulatory requirements.

Conclusion

Pressure vessels are critical engineering components that require meticulous design, precise material selection, and strict adherence to safety standards. Proper inspection and testing ensure structural integrity, reliable performance, and regulatory compliance throughout the vessel's operational life.

Advancements in materials, computational design, and manufacturing techniques continue to enhance the efficiency, durability, and safety of modern pressure vessels. By combining proven engineering practices with ongoing technological innovations, industries can safely manage high-pressure fluids and gases while minimizing risks and operational costs.