Storage Tanks – Types, Design Considerations, Materials of Construction, Inspection & Maintenance

Storage tanks are critical components of oil & gas, petrochemical, and industrial facilities. They are used to safely store a wide variety of liquids, including crude oil, refined petroleum products, chemicals, and water. This page provides a practical overview of the design, classification, operation, and maintenance of industrial storage tanks, focusing on key standards and engineering applications.

Purpose and Importance of Storage Tanks

In any process facility, storage tanks serve as buffers between production, processing, and distribution. They ensure continuous plant operation by compensating for flow rate variations and facilitating inventory management. From upstream crude oil storage to downstream blending and distribution terminals, tanks play a key role in both safety and logistics.

Their design must take into account fluid properties, environmental conditions, operating pressures, and industry codes. Poorly designed or maintained tanks can lead to leaks, contamination, fire hazards, or even catastrophic failures—making engineering diligence critical.

Classification of Storage Tanks

Storage tanks are typically classified based on the type of fluid they store, pressure requirements, and roof configuration. The two most common categories are atmospheric and pressurized tanks.

Atmospheric Storage Tanks operate at or near ambient pressure and are used for fluids like crude oil, diesel, or water. They are usually designed according to API 650 or similar standards.

Pressurized Tanks are designed to handle higher pressures and are suitable for storing LPG, ammonia, or other volatile substances. These tanks follow design standards such as API 620 or ASME Section VIII.

Tanks can also be aboveground or underground, depending on site conditions, safety requirements, and environmental regulations.

Types of Storage Tanks

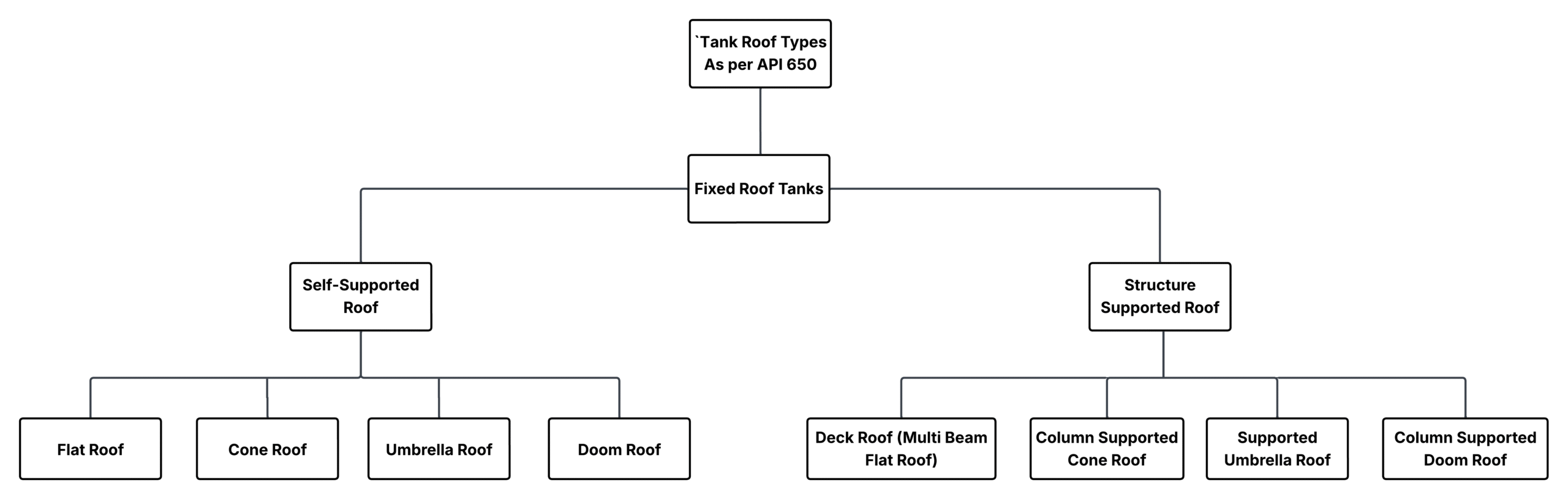

Fixed Roof Tanks

Fixed roof tanks represent one of the most fundamental and widely used storage solutions in industrial applications, primarily designed for maintaining stable liquids like water, diesel, and fuel oil. Characterized by their permanently affixed conical or dome-shaped roof structure, these tanks provide reliable containment while minimizing vapor space between the liquid surface and tank ceiling. A critical component is the breather valve (also called pressure-vacuum relief valve), which automatically regulates internal pressure by releasing vapors during filling operations and admitting air during product withdrawal.

The construction typically utilizes carbon steel or stainless steel materials depending on the stored product’s corrosiveness. These tanks can range in size from small 500-gallon units to massive million-gallon storage vessels. Fixed roof tanks are particularly favored for their simple design, cost-effectiveness, and low maintenance requirements compared to floating roof alternatives.

Environmental considerations include secondary containment systems to prevent leaks and insulation options for temperature-sensitive products. Common applications extend beyond petroleum to include chemical storage, agricultural uses, and municipal water reserves. Industry standards such as API 650 and ASME codes govern their fabrication to ensure structural integrity and safety compliance.

While unsuitable for highly volatile substances due to their fixed vapor space, their durability makes them ideal for long-term storage of stable liquids with minimal evaporation losses. Modern variants may also incorporate advanced monitoring systems for liquid level measurement and vapor recovery units to enhance environmental performance.

Fixed Cone Roof Storage Tank

Floating Roof Tanks

Floating roof tanks are specialized storage systems designed for volatile petroleum products like gasoline, crude oil, and chemical solvents. Their distinctive feature is a buoyant roof that rises and falls with the liquid level, effectively eliminating vapor space to dramatically reduce evaporation losses. These tanks come in two primary configurations: external floating roof (EFRT) designs where the roof is exposed to the atmosphere, and internal floating roof (IFRT) systems that feature a secondary fixed roof for additional protection. The floating deck typically incorporates sealing mechanisms to prevent product leakage while allowing smooth vertical movement. Common materials include aluminum or steel roofs with elastomeric seals that adapt to temperature-induced expansions.

Floating roofs are classified into different types based on their construction and design, each offering specific advantages in stability, evaporation control, and sun exposure protection.

Pan Floating Roof

The pan floating roof is the simplest type of floating roof. It consists of a large, flat pan slightly smaller in diameter than the tank shell. To minimize vapor loss and prevent leakage, it is equipped with a system of flexible shoes that close the gap between the roof edge and the tank shell.

Pontoon Floating Roof

The pontoon floating roof is constructed using a series of pontoons i.e., sealed compartments, arranged around its outer edge. This design improves buoyancy and stability while simplifying the overall roof structure.

Double-Deck Floating Roof

The double-deck floating roof features two layers of steel plates covering the tank’s entire area. The space between the upper and lower decks is divided into multiple compartments. This design prevents the stored liquid from coming into direct contact with a plate exposed to sunlight, thereby reducing heating of the liquid and minimizing evaporation losses.

Modern versions often include advanced vapor recovery systems and rim-mounted secondary seals to meet stringent environmental regulations. Their design significantly reduces both product loss and fire hazards compared to fixed roof tanks. API 650 Standard govern their construction, with additional requirements for secondary containment in ecologically sensitive areas. While requiring more maintenance than fixed roof tanks, their operational efficiency makes them indispensable for bulk storage of volatile liquids in refineries and terminals.

Horizontal Tanks

Horizontal storage tanks are widely used in industries such as petroleum, chemical processing, and water management due to their efficient design and versatility. These cylindrical vessels are typically constructed from steel for durability, though materials like fiberglass and polyethylene are also employed for specialized applications. To ensure structural integrity, their length is generally limited to no more than six times their diameter, preventing deformation under pressure. Standard features include pressure-vacuum vents to regulate internal conditions, gauge hatches for manual inspections, and sampling wells for liquid testing. When installed underground, these tanks often incorporate cathodic protection systems—either through sacrificial anodes or impressed current methods—to mitigate corrosion and extend operational life.

Maintenance and Industry-Specific Considerations

While horizontal tanks are robust, their longevity depends on proper maintenance and industry compliance. Refined petroleum products often contain corrosion inhibitors, which can inadvertently reduce the effectiveness of internal cathodic protection, necessitating supplemental coatings like epoxy or polyurethane. Regulatory standards such as API 650 for welded steel tanks and UL 142 for fire-resistant designs further dictate their construction and use. Common applications range from fuel storage (gasoline, diesel) to chemical containment (acids, solvents) and water management systems, making them indispensable in industrial infrastructure. By adhering to these engineering and maintenance protocols, operators can optimize both safety and performance.

Spherical and Bullet Tanks

Spherical (sphere) and horizontal bullet tanks are engineered for high-pressure storage of liquefied gases like LPG, hydrogen, and compressed natural gas. Their distinctive shapes – the sphere’s uniform curvature and the bullet tank’s cylindrical design with hemispherical ends – optimize structural integrity by evenly distributing internal stresses. These pressure vessels typically operate at 5-250 psi and are constructed from high-strength carbon steel or specialized alloys to withstand extreme pressures. Spherical tanks offer maximum volume efficiency for large-scale storage, while bullet tanks provide practical solutions for transportation and space-constrained installations. Both designs incorporate safety features including pressure relief valves, thermal insulation, and corrosion-resistant coatings. Manufactured to ASME Boiler and Pressure Vessel Code standards, they are critical for industrial gas storage, petrochemical plants, and energy sector applications where safe containment of volatile substances is paramount.

Storage Tank Design Considerations

Proper storage tank design is essential to ensure operational safety, structural stability, and full compliance with industry standards such as API 650 and API 620. A range of interdependent parameters must be evaluated to achieve a robust design:

Tank Diameter and Height: These are determined based on the required storage capacity, available plot space, tank farm layout, and the fluid’s properties. Designers must also account for freeboard, settling allowance, and operational levels.

Corrosion Allowance: An additional wall thickness (typically 1.5–3 mm) is incorporated into the design to compensate for long-term material degradation due to internal fluid corrosion or external atmospheric exposure.

Nozzles and Manways: Proper placement and sizing of nozzles, manways, and sumps ensure accessibility for filling, draining, sampling, inspection, venting, and instrument connections. Reinforcement around openings is also considered to maintain shell strength.

Foundation Design: Storage tanks are typically supported on ringwall foundations, slab-on-grade, or compacted gravel pads. The foundation design considers soil bearing capacity, differential settlement control, uplift resistance, and provision of drainage to prevent subgrade saturation.

Seismic and Wind Loads: In high-risk regions, tanks must be checked for seismic base shear, sloshing effects, anchorage needs, and wind-induced overturning or buckling. Design is done in accordance with API 650 Appendix E for seismic and Section 5.11 for wind.

In addition, all design calculations must incorporate factors such as internal design pressure or vacuum, operating and design temperatures, fluid density and viscosity, external corrosion exposure, maintenance access, and thermal expansion. Adherence to regulatory codes and local environmental requirements is also mandatory throughout the design process.

Storage Tank Materials and Construction Grades

Material selection for storage tanks in the oil, gas, and chemical process industries is a critical design consideration. It must ensure chemical compatibility, mechanical strength, weldability, corrosion resistance, and compliance with industry standards such as API 650 and API 620. The choice of material depends on the characteristics of the stored fluid (e.g., corrosiveness, temperature, pressure), environmental exposure, and intended service life.

Below are the most commonly used materials with their detailed descriptions and applications:

Carbon Steel

ASTM A36

- Description: Standard carbon structural steel with minimum yield strength of 250 MPa (36 ksi).

- Applications: Used in shell courses, bottoms, and roof structures of API 650 tanks for non-corrosive fluids such as water, diesel, or light hydrocarbons at ambient conditions.

ASTM A283 Grade C

- Description: Low-to-intermediate tensile strength carbon steel, with yield strength of 205 MPa (30 ksi).

- Applications: Suitable for atmospheric storage tanks with low pressure and low-temperature conditions.

ASTM A516 Grade 60 / 65 / 70

Description: Carbon steel plate for moderate and lower temperature service, with excellent notch toughness.

Grade 60: Yield strength ~240 MPa

Grade 65: Yield strength ~260 MPa

Grade 70: Yield strength ~275 MPa

Applications: Widely used for shell and bottom plates in tanks storing crude oil, sour service fluids (with added restrictions), and process fluids where toughness and strength are critical.

Low Alloy Steels

ASTM A537 Class 1

- Description: Pressure vessel quality steel with higher strength and notch toughness, normalized.

- Applications: Used in tanks requiring better mechanical properties under pressure, such as API 620 low-pressure tanks or elevated temperature services.

ASTM A633 Grade C / E

- Description: Normalized high-strength low-alloy structural steel for enhanced impact resistance.

- Applications: Tanks in cold climates or seismic zones requiring higher impact toughness.

Stainless Steels

ASTM A240 Type 304 / 304L

- Description: Austenitic stainless steel with good corrosion resistance.

- Applications: Suitable for storage of potable water, organic chemicals, or mildly corrosive fluids at ambient temperatures.

ASTM A240 Type 316 / 316L

Description: Similar to 304 but with added molybdenum for improved pitting resistance in chloride environments.

Applications: Used in chemical storage tanks containing brine, caustic soda, acids (e.g., acetic acid, sulfuric acid), or marine environments.

ASTM A240 Duplex 2205 (UNS S32205)

- Description: High-strength stainless steel with excellent chloride stress corrosion cracking resistance.

- Applications: Ideal for offshore applications, sour service, or highly corrosive chemical storage.

Aluminum Alloys

ASTM B209 5052 / 5083 / 6061

- Description: Corrosion-resistant, lightweight aluminum plates.

- Applications: Used for internal floating roofs, certain cone roofs, or tanks storing aviation fuels and oxidizing chemicals. Not suitable for high-pressure applications.

Non-Metallic and Composite Materials

FRP (Fiberglass Reinforced Plastic)

- Description: Composite material made of glass fiber and thermoset resin (e.g., vinyl ester or epoxy).

- Applications: Common in tanks for hydrochloric acid, sodium hypochlorite, wastewater, or effluents in chemical plants. FRP is corrosion-resistant and lightweight but has temperature and mechanical limitations.

Lined Carbon Steel

- Description: Internally lined steel tanks using vulcanized rubber sheets, epoxy coatings, or glass flake linings.

- Applications: Cost-effective solution for storing corrosive acids (e.g., HCl, H₂SO₄), caustics, and brine water when full stainless steel construction is economically infeasible.

Additional Considerations for Material Selection:

- Corrosion Allowance: Typically ranges from 1.5 mm to 3 mm depending on product aggressiveness and service life.

- Post-Weld Heat Treatment (PWHT): Required for thicker materials or specific alloy grades, especially in sour service.

- Compatibility with Internal Lining: Some coatings or linings may limit the material types that can be used.

- Temperature and Pressure Range: Materials must comply with the design conditions defined under API 650 (up to 93°C and near-atmospheric pressure) or API 620 (low-pressure, up to 260°C).

- H₂S or Sour Service Suitability: Requires notch-tough materials with low sulfur content and hardness control as per NACE MR0175/ISO 15156.

Tank Inspection and Testing

Regular inspection and testing are essential to ensure safe operation and regulatory compliance. Storage tanks are inspected both externally and internally at fixed intervals.

Common Inspection Methods:

- Visual Inspection for corrosion, cracks, and structural damage

- Ultrasonic Thickness Testing (UTT) to measure wall thickness and detect thinning

- Magnetic Particle or Dye Penetrant Testing for crack detection

- Hydrostatic Testing to verify tank integrity before commissioning or after major repairs

- API 653 Inspections for aboveground atmospheric tanks, including fitness-for-service evaluations

Digital inspection tools, drones, and robotic crawlers are increasingly used for more efficient, accurate, and safer inspections.

To learn more about inspection and testing related content follow Static Equipment Inspection page.

Maintenance and Repair of Storage Tanks

Tank maintenance includes both routine and corrective actions aimed at extending service life and preventing failures. Common maintenance activities include:

- Repainting and coating applications to prevent corrosion

- Replacing gaskets, nozzles, or floating roof seals

- Welding patch plates on damaged shell or bottom areas

- Cleaning tanks before inspection or change of service

- Cathodic protection system checks and maintenance

Maintenance shutdowns should be planned well in advance with detailed scope, job cards, permits, and safety measures in place.

Safety and Environmental Protection

Safety and environmental protection are critical aspects of storage tank design, operation, and maintenance. Tanks often contain hazardous or flammable substances, which, if not properly managed, can lead to accidents, fires, or environmental contamination. To ensure safe operation, tanks are equipped with engineered systems and protective features designed to prevent incidents and reduce risk.

Key Safety Features

Overfill Protection: Tanks are fitted with level sensors, high-level alarms, and automatic emergency shutoff valves to prevent product overflow, reducing the risk of spillage and fire hazards.

Vapor Recovery Systems: Volatile Organic Compounds (VOCs) are controlled through vapor recovery units, ensuring compliance with air-quality standards and minimizing emissions to the atmosphere.

Containment Systems: Bund walls and containment dykes are constructed around tanks to capture any accidental leaks or spills, preventing soil and groundwater contamination.

Fire and Explosion Protection: Flame arrestors, pressure/vacuum relief valves, and foam pourers are installed to protect against fire escalation and to maintain safe internal tank pressure.

Safe Access for Operators: Ladders, platforms, handrails, and fall protection systems are provided to ensure personnel can carry out inspection and maintenance tasks safely.

Regulatory Compliance

Storage tanks must comply with internationally recognized codes and standards such as API (American Petroleum Institute), OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Association), and relevant local environmental regulations. Adhering to these requirements ensures that tank facilities are not only safe and reliable but also environmentally responsible.

Implementing these safety and environmental protection measures not only safeguards human life and the surrounding ecosystem but also helps facility owners avoid costly incidents, regulatory penalties, and operational downtime. A well-designed safety system is therefore an essential part of any storage tank installation.