Heat Exchangers: Working Principle, Types, Configurations, and Selection

Heat exchangers are critical devices in industrial and process systems, enabling efficient heat transfer between fluids without mixing.

Understanding their working principle, types, configurations, and selection criteria is essential for engineers and process designers to ensure energy efficiency, process stability, and optimal thermal performance.

1. Working Principle of Heat Exchangers

Heat exchangers operate on the fundamental principles of thermal conduction and convection, transferring heat from a hot fluid to a cold fluid without mixing them. A solid barrier, typically metal, separates the two fluids, allowing heat to flow through its surface. The efficiency of heat transfer depends on factors such as fluid temperature difference, flow arrangement, thermal conductivity of the material, and the surface area in contact with the fluids.

Common flow arrangements include parallel flow, counter flow, and cross flow, each influencing the temperature profile and overall heat transfer efficiency. For example, in a counter-flow arrangement, fluids move in opposite directions, maximizing the temperature difference and improving efficiency compared to parallel flow.

2. Flow Arrangements of Heat Exchangers

The flow arrangement in a heat exchanger determines how the hot and cold fluids move relative to each other, directly impacting heat transfer efficiency, temperature profiles, and pressure drops. The most common arrangements are:

2.1 Parallel Flow:

In this arrangement, both the hot and cold fluids move in the same direction. While it is simple to design and construct, the efficiency is generally lower because the temperature difference between the fluids decreases along the length of the exchanger.

2.2 Counter Flow:

Fluids move in opposite directions. Counter-flow maintains a higher temperature difference along the length of the exchanger, resulting in more efficient heat transfer. It is widely used in industrial applications where high efficiency is required.

2.3 Cross Flow:

Fluids move perpendicular to each other. This configuration is common in air-cooled or compact heat exchangers, providing moderate efficiency and allowing easier construction in limited spaces.

3. Types of Heat Exchangers

Heat exchangers are designed in various configurations to meet different thermal, mechanical, and space requirements. The most commonly used types include:

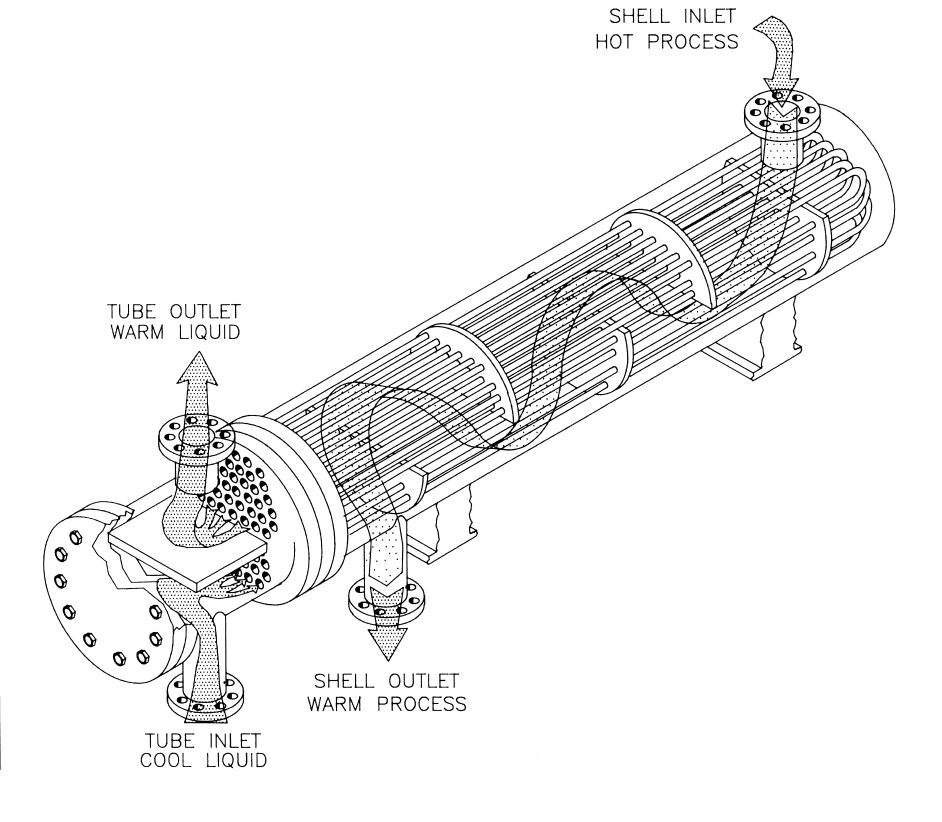

3.1 Shell and Tube Heat Exchanger

Structure:

- The shell and tube heat exchanger is composed of a cylindrical shell that encloses a bundle of tubes. One fluid flows through the tubes (tube-side), while another fluid flows across the tubes within the shell (shell-side), allowing heat transfer through the tube walls.

- Tube sheets at both ends secure the tubes and isolate the two fluids, while baffles inside the shell guide the shell-side fluid to flow across the tubes repeatedly, enhancing turbulence and thermal exchange.

- The design may include removable tube bundles, floating heads, or U-tube configurations depending on maintenance needs and thermal expansion considerations.

Working Principle:

- Heat is transferred indirectly between two fluids—one flowing inside the tubes and the other outside them—without mixing. The tube walls act as the conductive barrier.

- Baffles redirect the shell-side flow to increase contact with the tube surfaces, promoting turbulence and improving convective heat transfer.

- Counter-current flow arrangements are often preferred over co-current flow, as they maintain a higher temperature gradient across the exchanger, boosting efficiency.

Advantages:

- These exchangers can withstand high pressures and temperatures, making them suitable for demanding industrial applications such as steam generation and hydrocarbon processing.

- Their modular design allows for easy maintenance—tube bundles can be removed and replaced without dismantling the entire unit, reducing downtime.

- Multiple pass configurations on either side can be implemented to increase heat transfer surface area and improve thermal performance.

- A wide range of materials can be used for the tubes, including stainless steel, copper, and titanium, allowing compatibility with corrosive or high-temperature fluids.

- The design is highly scalable, enabling customization of shell diameter, tube count, and length to meet specific process requirements.

Disadvantages:

- Shell and tube exchangers require a relatively large footprint, which can be a limitation in space-constrained facilities or offshore platforms.

- The initial cost is higher due to the need for pressure-rated materials, precision fabrication, and compliance with design codes such as ASME and TEMA.

- Fouling on tube surfaces is common in services involving dirty or viscous fluids, necessitating regular cleaning and inspection to maintain efficiency.

- The design and sizing process is complex, requiring detailed thermal and mechanical analysis to ensure safe and optimal performance under varying operating conditions.

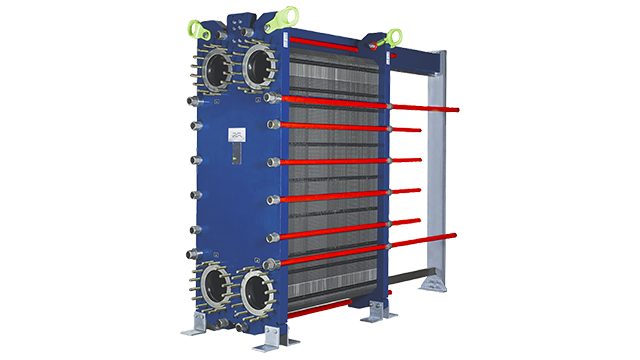

3.2 Plate Heat Exchanger

Structure: Composed of multiple thin, corrugated metal plates stacked to form separate channels for hot and cold fluids. Heat transfers through the plates.

Advantages: High thermal efficiency, compact, easy to expand or service.

Disadvantages: Limited to lower pressure and temperature, gasketed types may leak, not ideal for fouling fluids.

Example Applications: HVAC, refrigeration, food processing.

3.3 Air-Cooled Heat Exchanger

Structure: Uses ambient air to cool fluids via finned tubes and fans. No water is required for cooling.

Advantages: Water-free operation, environmentally friendly, easy outdoor installation.

Disadvantages: Large physical size, efficiency depends on ambient temperature, higher fan power consumption.

Example Applications: Power plants, refineries, gas compression stations.

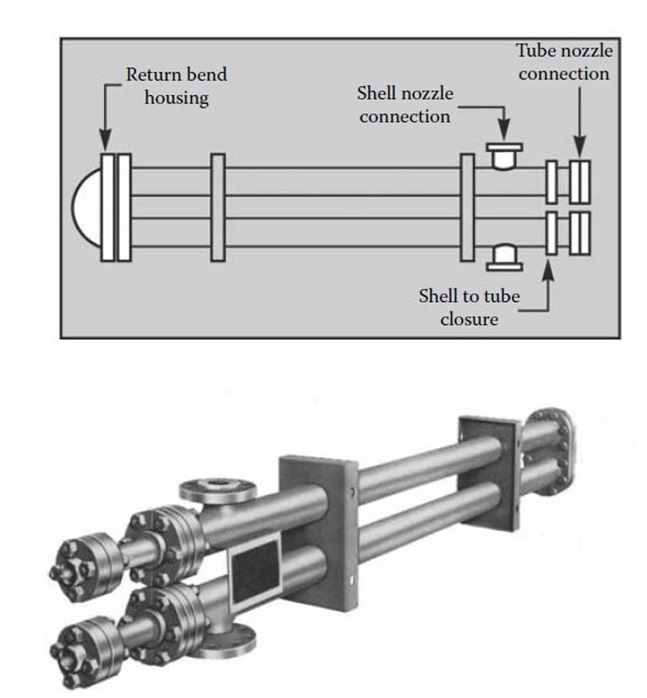

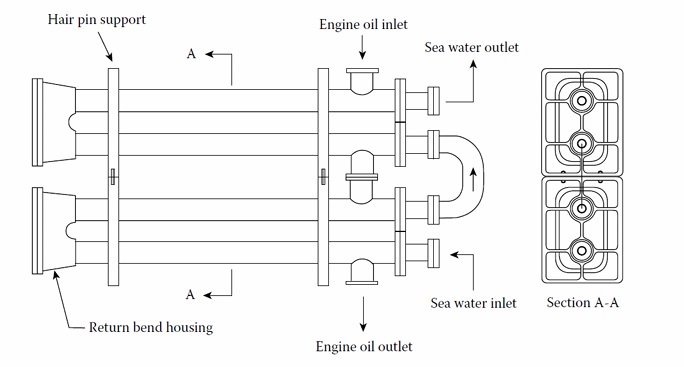

3.4 Double Pipe Heat Exchanger

Structure: A double-pipe heat exchanger typically consists of two pipes—one placed concentrically inside the other. The inner pipe (tube side) carries one fluid, while the outer pipe allows the second fluid to flow through the annular space. Suitable fittings are used to guide the flow between sections, as illustrated in the figure below. The inner pipe is often connected using U-shaped bends, enclosed within return housings.

These exchangers can be connected in series or parallel to satisfy specific pressure drop and mean temperature difference (MTD) requirements. They are mainly employed for sensible heating or cooling of process fluids where the heat transfer area is relatively small (up to about 50 m²). Owing to the smaller pipe diameters, this design is ideal when one or both fluids operate under high pressure. However, a notable drawback is their bulkiness and higher cost per unit of heat transfer area compared to other exchanger types.

Double-pipe exchangers are also referred to as hairpin heat exchangers. They are effective when handling a gas, viscous liquid, or small flow volumes. Additionally, they perform well under fouling conditions because they can be easily dismantled for cleaning and maintenance.

Advantages: Its simple and robust design allows for easy maintenance and cleaning. This makes it highly suitable for small-scale applications or services involving high temperatures and pressures.

Disadvantages:It offers a limited heat transfer area, making it physically bulky and inefficient for large-capacity duties. Consequently, it is not cost-effective for most large-scale industrial processes.

Example Applications: Preheating, cooling, heat recovery in small chemical or HVAC systems.

3.5 Spiral / Plate-Fin Heat Exchanger

Structure: Spiral or finned channels maximize surface area in a compact design.

Advantages: High efficiency, compact, handles phase change fluids.

Disadvantages: More complex construction, higher fabrication cost.

Example Applications: Cryogenic processes, gas processing, space-constrained installations.

4. Configurations of Heat Exchangers

Heat exchanger configurations determine the flow path, number of passes, and overall thermal performance. Choosing the right configuration ensures optimal efficiency and pressure drop control.

4.1 Shell & Tube Pass Arrangements:

Shell and tube exchangers can have single or multiple passes for both shell-side and tube-side fluids. Common arrangements include:

- 1-1 Pass: Single pass on both shell and tube sides. Simple design with moderate efficiency.

- 1-2 Pass: Single pass on shell side, two passes on tube side. Improves heat transfer and temperature approach.

- 2-4 Pass: Two passes on shell side, four passes on tube side. Used for high heat duty applications.

4.2 Multi-Pass Plate Heat Exchangers:

Plate heat exchangers can be configured in multiple passes by arranging plates alternately, allowing higher heat transfer and better temperature control.

4.3 Compact and Modular Designs:

Compact exchangers, such as plate-fin or spiral types, maximize surface area in a small footprint. Modular designs allow capacity adjustment, easy maintenance, and flexibility for future expansion.

Selecting the appropriate configuration depends on the required heat duty, flow arrangement, pressure drop limitations, fluid properties, and space constraints.

5. Selection Criteria for Heat Exchangers

Choosing the right heat exchanger is crucial to achieving efficient thermal performance, reliability, and cost-effectiveness. Selection should be based on a combination of thermal, mechanical, and operational factors.

5.1 Heat Duty:

Determine the required heat transfer rate based on the temperature change and flow rates of the fluids. The heat duty drives the size and type of the exchanger.

5.2 Fluid Properties:

Consider viscosity, density, corrosiveness, and fouling tendencies. Some exchangers are better suited for clean fluids, while others can handle fouling or abrasive fluids.

5.3 Pressure Drop Limitations:

Excessive pressure drops reduce system efficiency. Choose configurations and types that minimize pressure loss while maintaining effective heat transfer.

5.4 Temperature Range and Approach:

The maximum and minimum temperatures of the fluids affect material selection and exchanger type. Counter-flow arrangements are preferred for closer temperature approaches.

5.5 Space and Installation Constraints:

Evaluate available space, accessibility, and ease of installation. Compact or modular designs may be necessary for limited areas.

5.6 Maintenance and Cleaning Requirements:

Consider ease of disassembly, cleaning, and inspection. Plate and modular designs offer easier maintenance compared to large shell-and-tube units.

5.7 Material Selection:

Choose materials compatible with fluid chemistry, operating temperatures, and pressures to ensure long-term durability and corrosion resistance.

By evaluating these criteria, engineers can select the most suitable heat exchanger type and configuration for any industrial or process application.

6. Operational Considerations for Heat Exchangers

Proper operation and maintenance of heat exchangers are essential to ensure consistent performance, longevity, and safety. Several factors should be considered during operation:

6.1 Fouling and Scaling:

Deposits from fluids can accumulate on heat transfer surfaces, reducing efficiency and increasing pressure drop. Regular monitoring and cleaning schedules help prevent performance loss.

6.2 Corrosion and Material Compatibility:

Fluids may be corrosive, requiring selection of resistant materials such as stainless steel, titanium, or specialized alloys to extend service life.

6.3 Thermal Stress:

Rapid temperature changes can cause expansion and contraction, leading to fatigue or cracks. Gradual start-up and proper design reduce thermal stress.

6.4 Pressure and Flow Monitoring:

Maintaining proper flow rates and pressures ensures efficient heat transfer and prevents mechanical damage to the exchanger.

6.5 Maintenance and Inspection:

Modular and accessible designs facilitate periodic inspection, cleaning, and repair, reducing downtime and extending operational life.

Attention to these operational considerations ensures optimal heat exchanger performance, reliability, and safe operation over time.

7. Advantages of Heat Exchangers

Heat exchangers offer numerous benefits in industrial and process applications by optimizing thermal management and improving system efficiency.

7.1 Energy Efficiency:

Heat exchangers recover waste heat from process streams, reducing fuel consumption and lowering operational costs.

One of the most significant benefits of heat exchangers is their ability to improve overall energy efficiency. By transferring heat between fluids effectively, they reduce the need for additional heating, saving fuel and energy in industrial processes.

Heat exchangers also help minimize utility costs by recovering heat from exhaust gases, hot liquids, or steam. This recovered energy can preheat incoming fluids, reducing reliance on external heating or cooling systems and lowering electricity and fuel expenses.

7.2 Process Control and Stability:

Maintaining consistent temperatures improves product quality, reaction rates, and prevents thermal fluctuations that could stress equipment.

Heat exchangers contribute to better process control by maintaining consistent temperatures, which is crucial for product quality and safety.

Precise Temperature Regulation: Heat exchangers ensure that fluids reach and maintain the desired temperature, preventing overheating or undercooling in sensitive processes.

Improved Reaction Rates: In chemical and pharmaceutical industries, maintaining optimal temperatures enhances reaction efficiency and product yield.

Stable Operations: By preventing thermal fluctuations, heat exchangers help avoid equipment stress and process disruptions.

7.3 Environmental Benefits:

Efficient heat transfer reduces energy waste, lowers greenhouse gas emissions, and can minimize water consumption in cooling applications.Heat exchangers support sustainable industrial practices by reducing emissions and energy waste. Lower Carbon Footprint: Reusing waste heat decreases the demand for fossil fuels, reducing greenhouse gas emissions.Compliance with Regulations: Many industries must adhere to environmental standards, and heat exchangers help meet energy efficiency and emission control requirements.

Reduced Water Usage: In cooling applications, heat exchangers can recycle water, minimizing consumption and wastewater generation.

7.4 Versatility:

Multiple types and configurations allow heat exchangers to handle gases, liquids, and multiphase flows, adapting to diverse industrial needs. Heat exchangers come in various designs (shell-and-tube, plate, air-cooled, etc.), making them suitable for diverse applications.Wide Range of Applications: Used in heating, cooling, condensation, evaporation, and heat recovery across multiple industries.

Compact and Modular Designs: Plate heat exchangers, for example, offer high efficiency in a small footprint, ideal for space-constrained facilities.

Compatibility with Different Fluids: Heat exchangers can handle gases, liquids, and even multiphase flows, making them adaptable to various industrial needs.

7.5 Extended Equipment Life: Proper thermal management prevents overheating, reduces thermal stress, and protects machinery from premature wear. By optimizing thermal management, heat exchangers reduce wear and tear on industrial machinery.

Prevents Overheating: Excessive heat can damage equipment, but heat exchangers help maintain safe operating temperatures.

Reduces Thermal Stress: Consistent temperature control minimizes expansion and contraction stresses in pipes and reactors.

Corrosion Resistance: Advanced materials (stainless steel, titanium, alloys) in heat exchangers resist corrosion, ensuring long-term durability.

7.6 Maintenance Efficiency:

Modular and accessible designs simplify inspection, cleaning, and repair, minimizing downtime and extending service life. Modern heat exchangers are designed for easy maintenance and reliability.Self-Cleaning Options: Some designs (like spiral or scraped-surface heat exchangers) minimize fouling, reducing cleaning frequency.

Easy Inspection and Repair: Modular designs allow for quick disassembly and maintenance without shutting down entire processes.

Long Service Life: High-quality materials and efficient designs ensure minimal breakdowns and extended operational life.

8. Conclusion

Heat exchangers are essential components in industrial and process systems, enabling efficient heat transfer between fluids while maintaining separation. Understanding their working principles, flow arrangements, types, configurations, and selection criteria is crucial for engineers to optimize thermal performance, reduce energy consumption, and ensure process stability.

By selecting the appropriate type and configuration, considering operational requirements, and maintaining proper operation, heat exchangers can provide reliable, efficient, and long-lasting performance across a wide range of applications. Their versatility, efficiency, and adaptability make them indispensable in modern industrial processes.